The 6.0L is a favorite of ours at Absolute Power Stroke. We believe it has the best combination of power, reliability and cost of ownership. Although it has a reputation to be troublesome and unreliable, we believe that it has a special place in history. It has the ability to start very well in the cold, make lots of power and get great fuel mileage. With the proper upgrades, this engine can be a very reliable performer while used as a daily driver or as a tow rig. The 6.0L equipped Super Duty’s are modern, comfortable and durable trucks.

Lack of maintenance, as usual, can plague a 6.0L into costly repairs and downtime. One of the biggest issues we see in our shop is inadequate repair procedures performed while using inferior, cheap parts. Almost always, OEM parts are the best choice when repairing these engines. Usually other shops focus on fixing the result of a failure, not the cause. This is especially true for the 6.0L. Endless hours can be wasted if the proper diagnostic routines are not performed for the specific symptoms. Throwing parts at this engine in hopes of solving the issue will only run up the repair bill. If this engine is maintained and repaired properly, with the proper parts, it has the durability to last for hundreds of thousands of miles.

Some services can be combined for savings in labour. Prices reflect single services for a single price. Please call for more details and see how we can help today.

| Service Offered | Price |

|---|---|

| Engine Oil Change: 15W40 and Motorcraft oil and filter | $120 |

| Fuel Filter Service: Motorcraft filters | $196 |

| Coolant Flush: Includes extended life coolant, thermostat, rad cap, flush kit | $259 |

| Rear Differential Service: SRW 75W140 Synthetic oil | $180 |

| Front Differential Service: SRW 80W90 oil | $120 |

| Rear Pinion Seal: SRW | $163 |

| Front Hub Seals: SRW 2003-2004 both sides | $442 |

| Front Hub Seals: SRW 2005-2007 both sides | $356 |

| Glow Plugs replaced: 8 Motorcraft plugs | $444 |

*Please call to confirm prices.

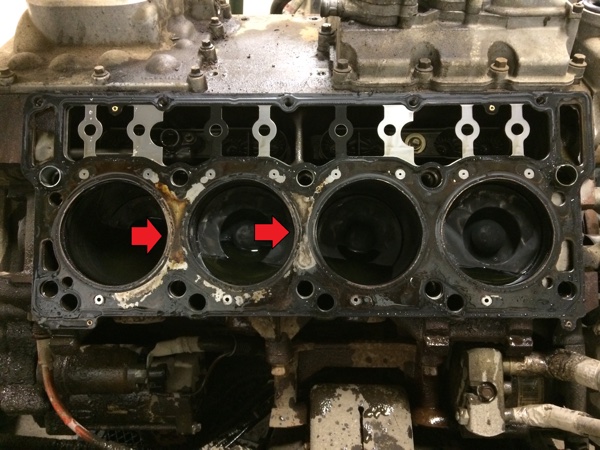

Here we have a 6.0L head gasket failure. The gaskets were replaced less than 10,000kms ago and have failed again. ARP studs were already used and the heads were planed and rebuilt but the gaskets still failed. These are the early Victor Reinz Black Onyx version gaskets. They don’t stand up at all on these engines and are pretty much a guaranteed repeat failure once installed. Note the points on the gasket where combustion gas pushed past the gasket and entered the water jacket of the engine. Each side had multiple failure points.

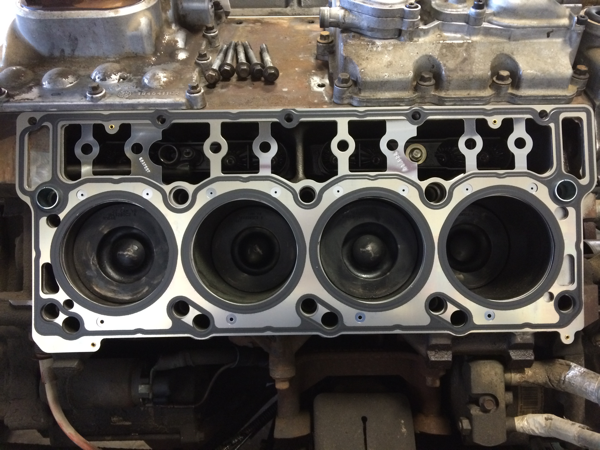

We installed a set of Victor Reinz Black Diamond gaskets which are the latest version. They are made by Mahle, who manufactures the OE gaskets for Ford/Navistar. They are made on the same punch presses with the same material as the OE version using the same sealing compound. The only difference is the color of the sealing compound, black instead of the OE blue. The cost savings is huge when you don’t need the factory head bolts, as this is the only way to buy gaskets from Ford. We reused the customers ARP head studs and got him back on the road.

This 2004 Super Duty came in for steering and suspension work. With every truck that comes in to our shop, it gets put through a series of checks and diagnosis regardless of what work it came in for. The fuel pressure was also checked with a manual gauge while road testing. The fuel pressure would dip to 40 psi under heavy load and would average around 45 psi. During the repair, an updated fuel pressure regulator kit (p/n: 3C3Z-9T517-AG) or “Blue Spring Kit” was installed. After repairs were complete the trucks fuel pressure would run as high as 65 psi and around 60 psi under load. The increased fuel pressure will help extend the life of the engines injectors, keep injector crackle to a minimum and help with overall performance.

We love challenges at Absolute Power Stroke and this truck was no exception. This 2003 Excursion 6.0L with 300,000 kms came in with a hard start and heavy surge when cold. No matter if it were summer or winter, this truck would sometimes stall after first started cold and would always surge heavily for the first few minutes until partially warmed up. Once warm, it would run fine and not miss a beat. It had head gaskets replaced not too long ago and in an attempt to fix the surging problem new set of fuel injectors and FICM were installed at another shop by the previous owner. Using the IDS to monitor the engine parameters, it was noticed that the engine oil temp was about 23F colder than the coolant temp before the engine was even started, cold. The PCM uses the oil temp, among other parameters, to determine fueling, glow plug time, etc. to aid start up. The PCM constantly thought it was much colder than it actually was and would over compensate for the temperature causing a heavy surge after start up. The intake air temp sensor was also out by 10F, colder. The engine oil temperature sensor was examined and looked to be almost brand new. The PCM connector was removed and found 2 pins crossed and damaged. The engine oil temp and intake air temp sensor pins, together! This was the cause of the inaccurate readings. Once they were straightened and repairs made, the truck would not surge at all after start up! Over and over it was tested and it never missed a beat! The owner was thrilled and drove the truck home.

About a while later the customer called back and said sometimes after the truck sits for a few days, it will start and die on the first attempt. So back it came. Determined to diagnose this truck we dug our teeth in! Every part of the truck was scrutinized. The biggest issue was that the truck would have to sit for two days and be started on the third to recreate the problem. This was especially frustrating since you only had one shot to record and test anything. So every third day the truck was started and certain things checked. Some small things were addressed right away. The WIF light was on, a contaminated fuel pump module with a build-up of crud inside the housing. The batteries were weak and worn out, replaced and cleaned connections. The ICP sensor had oil protruding through it, replaced sensor and installed new pigtail. The fuel pressure was tested again. Passing pressure requirements, the upper fuel bowel would drain back and empty out completely after it was parked. An oring kit, new filter and cap were installed. It turned out the housing itself would allow air to seep in from around the cap. The fuel bowl was replaced with a reconditioned 2005 version and the corresponding fuel lines with built in check valve were installed.

This solved the fuel draining back but the truck still started and stalled! Using the IDS and its recording feature, the high pressure oil system went under the magnifying glass. There were no performance issues or leaks that could be detected once running but something wasn’t right while it cranked over! The pump would provide pressure right away while cranking but couldn’t keep up once the engine fired. This all happens very fast and without the IDS software it most likely would have been missed or over looked. The system was air tested through the IPR socket in the pump cover and air was heard through the oil filter housing. Bingo! In short, excessive air returning to the oil filter is a sign of a bad pump. The 2003 and 2004 6.0L with the aluminum bodied pumps can give problems, especially later in their life. This one would work fine when running but just wouldn’t give the kick necessary upon first start up to keep the engine going. An air lock or oil drain back most likely caused the issue after sitting for more than two days. A new pump was installed and re-air tested. No returning air to the oil filter! Everything was cleaned before reassembly and road tested to verify the repair. The truck starts and runs like new and another happy customer is added to the list.